Description

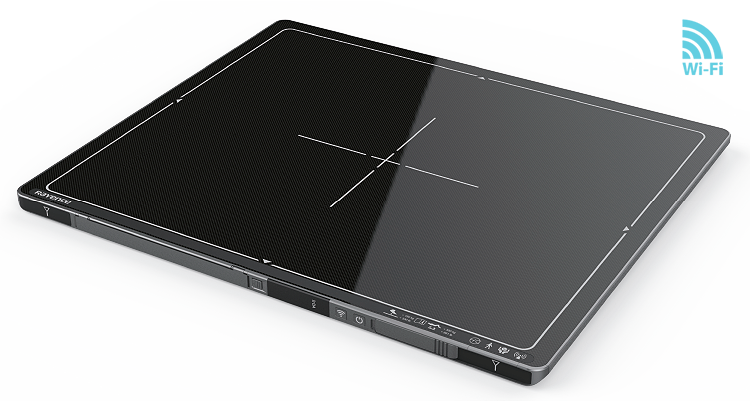

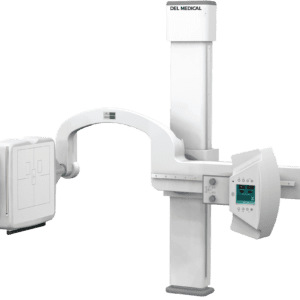

The ergonomically designed C-Series Cesium Iodide and Gadolinium Oxysulfide wireless detectors are designed to offer new levels of handling, functionality and exceptional diagnostic image quality in the X-ray room and beyond. The compact and lightweight Xmaru 1012 Wireless Digital Flat Panel Detectors are well designed to satisfy the daily diagnostic needs of the most demanding user.

- Tapered, Recessed Edges

- Thin and Lightweight Design

- Optional Portable Battery Charger

- Image Storage Up To 200 Images

- Room Sharing Functionality

- Auto Triggering Technology

The detector’s high Detector Quantum Efficiency (DQE) achieves superb image quality with low patient dose.

Specifications

The detector’s high Detector Quantum Efficiency (DQE) achieves superb image quality with low patient dose.

Supporting up to 660 lbs, the detector is manufactured with a shock, vibration, and scratch resistant carbon fiber composition.Water Resistant (IP 66) The detector is water resistant to most typical water spills in a hospital as well as in outdoor applicants.

- Scintillator Cesium Iodide (CsI)

- High Image Quality with spatial resolution of 140 ㎛ Limiting resolution:2.5 – 3.93 lp/mm

- Pixel matrix: 3268 x 2756

- Wide active area of 16.7 x 14 inch

- Wireless data transfer

- Dimensions:18.1 x 15.1 x 0.6 in Weight: 6.6 lbs

- Bit depth (A/D):14/16 bit

- Image display:≤ 2 Sec.. Cycle time:6 sec.

- 1 Year Warranty

Acquisition Workstation

XmaruView is a flexible image acquisition software for today’s diagnostic imaging providers. The XmaruView (XV) console drives the Xmaru Panel Series to its full potential using industry’s most advanced image processing algorithms for the highest quality diagnostic images.

The XV software comes with standard features like DICOM Modality Work List (MWL), Image Stitching, DICOM Printing, and DVD/CD Burning with viewer.

An important feature offered with the XmaruView is Analysis Statistic Report (ASR). The Analysis Statistics Report keeps track of your image acceptance, rejections, retakes and deletion rates. With the assistance of industry professionals, the XV software optimizes workflow with an easy to navigate GUI.

Features

- DICOM File Management and Printing

- Image Magnification

- Image Stitching

- CD recording with CD viewer

- Measuring the Length and Angles of the Image

- Adding Annotation Text, Graphics and Electronic Markers to an Image

Harmonic Stitching (optional)

Image stitching is achieved by selecting one of three methods: Full-Auto, Semi-Auto or Manual. To eliminate the exposure borders of each image due to varying densities, Rayence’s advanced gradation process is automatically applied. Together with Rayence’s optional automatic stitching software, up to three views can be automatically stitched at a touch of a button, making stitching examinations easier than ever to attain.

Intuitive GUI

Intuitive and Direct Graphic User Interface with X-ray Detector and Generator

Optimized Exposure Conditions and Image Review

Reducing Unnecessary Rework and Test

System Requirement

Monitor Resolution 1,280 x 768 (Minimum) 1,680 x 1,050 1,920 x 1,080 (Optimized) CPU (min) Intel Core™ i5 (min) Memory Intel GMA 950 (min) Intel GMA X3500 (min) Nvidia Geforce FX5200 (min) 512MB

(No Shared Memory) Operation System Windows 10 64bit Professional System requirements subject to change without prior notice.